Taking Food Safety to the Source

As businesses providing ready-to-eat foods, co-ops should be taking precautions to ensure that we are not contributing to the statistics on food-borne illness. With an estimated 1.5 million people in the United States experiencing some form of food-borne illness every week, it stands to reason that some of them are getting sick from foods prepared outside the home.

At the Hanover Co-op in Hanover, New Hampshire, we use a food safety system called Hazard Analysis Critical Control Points (HACCP), a program originally designed for people very far from home.

Infants and astronauts

Although anyone can fall victim to food-borne illness, certain populations have greater potential to suffer dangerous complications. An epidemiologist will tell you that those most at risk from food-borne illness are the elderly, the very young, those with compromised immune systems, and pregnant women.

The National Aeronautics and Space Administration (NASA) added one more group—astronauts. In 1959, while planning the first manned space flights, NASA realized that food poisoning could prove disastrous to a space mission. When they commissioned The Pillsbury Company to provide astronauts with food that could be handled under zero gravity conditions, they also mandated that it be as free as humanly possible from bacterial, physical, and chemical contamination. Pillsbury responded by developing HACCP.

Today, HACCP (pronounced “has-sip”) procedures are mandatory for meat, poultry, and seafood processing plants in the United States and are also used by other sectors of the food industry, especially those in the middle of the food production chain. HACCP in foodservice, however, is relatively unknown.

HACCP at Hanover Co-op

In 2000, the Hanover Co-op opened its first off-site production kitchen to provide both hot and cold prepared foods to our two supermarkets and smaller community market. Known as the Commissary Kitchen, this state-of-the-art facility allowed our professional staff of chefs and cooks to concentrate on efficient, quality food production without the distractions and inconveniences of our former behind-the-counter in-store kitchens. It also allowed our food production manager, Executive Chef Aron Tomlinson, to design a facility with food safety in mind—a place where he could establish and enforce a HACCP plan intended to make the Hanover Co-op’s prepared foods production a model of safe food practices.

“We learned a lot from working under less-than-ideal circumstances in the stores,” Tomlinson says. “In this kitchen, we put in a blast chiller for fast cooling and placed the ice machine near a sink to create a chill sink for pots of soup. We made sure we had touchless hand sinks and touchless soap dispensers.”

A separate facility also made it easier to create a culture of food safety among staff and allowed Tomlinson to control all aspects of production, from receiving of ingredients to transport of finished product.

“In the stores, we had no control over how food was handled in receiving, but here our receiver is part of the kitchen staff,” Tomlinson explains. “Our drivers know to separate raw meat from cooked foods during transportation. Prep staff are surrounded by other people who do nothing but handle food all day. That makes it easier to remember things like washing your hands after leaving the break room.”

Putting HACCP to work

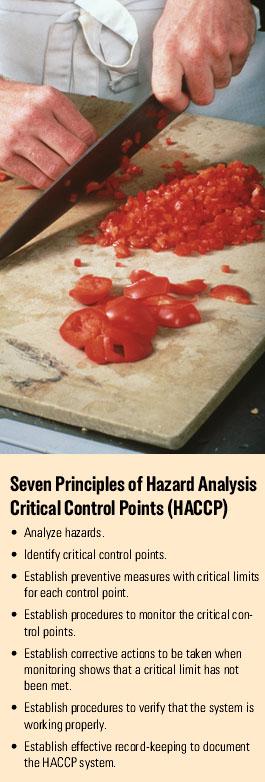

Upon reading an official definition of HACCP, one could justifiably throw in the towel before starting. To wit: “HACCP is a dynamic process, incorporating seven principles, that identifies the critical points in the flow of food production where hazards can be prevented, eliminated, or reduced to safe levels; then sets critical limits; and provides a plan for monitoring, corrective action, and documentation to achieve a safe product.” Yet, once one understands the process, it makes perfect sense.

Co-ops might even find reassurance in the parallels between seven cooperative principles and seven HACCP principles, or the resemblance to policy governance in its development of a set of critical limitations to be acted upon, monitored, and reported.

Essentially, HACCP is based on the idea that knowledge is power. If we know where potential hazards lurk in a food’s flow through our establishment, we can take steps to control them. By identifying potential hazards—biological, chemical, or physical—and then intervening at the critical control points (CCP) with appropriate measures, we can prevent, eliminate, or reduce hazards to an acceptable level.

For example, cooking, cooling, holding, and reheating are typical CCPs for an item like soup. Critical limits must be established for the temperatures to which the soup is taken and maintained at each of these points. Cooling limits must also include the time allowed for the soup to reach a safe temperature—hence the use of a blast chiller or cooling sink to meet the specified time limit.

Monitoring is essential to establishing that critical limits are being met, and so employees are trained to record time and temperature, pH, or whatever parameter has been identified as a CCP for a particular food. The HACCP plan also clearly defines what corrective action to take if a critical limit is not met. A corrective action might be as simple as continuing to cook until the required minimum internal temperature is reached, or as drastic as throwing away food that has been held at unsafe temperatures for an unknown amount of time.

The final two principles of HACCP involve verifying that the system works and establishing procedures for documentation and record keeping. Are employees following the plan as written? Are our critical control points and limits still appropriate? How often have we needed to take corrective action? Have we received any food-borne illness complaints?

Additional documentation might include calibration records for thermometers, monitoring schedules, equipment maintenance, and so on, as well as our standard operating procedures.

Everybody’s different

While it’s tempting to think that our HACCP plan could simply be shared with others, the truth is that each co-op must develop a plan that addresses the hazards specific to its own menu, facilities, equipment, and systems. It must also have a strong foundation upon which to build a plan, including thorough understanding of food safety issues through ServSafe or other training and established food safety procedures for employees and suppliers.

For background, see “Creating a Culture of Food Safety,” Cooperative Grocer No. 112, May-June 2004).